Agentic Manufacturing Operations Platform

Computer vision–driven AI agents that observe production, reason in real time, and trigger autonomous operational actions across food and beverage manufacturing, delivering measurable line efficiency.

Why Agentic Manufacturing Operations?

Traditional systems observe. Agentic Manufacturing Operations observe, reason, and act. Automatically.

Traditional manufacturing systems observe and report

Most factories rely on systems that generate data after the fact, leaving teams to react manually to issues already impacting yield, compliance, and throughput.

Manual checks limit speed, scale, and accuracy

Human inspection slows lines and introduces variability, allowing defects, mislabels, and counting errors to slip through undetected.

Many recall risks are identified too late

Issues are often discovered downstream or by retailers, when corrective action is most expensive and reputational damage is unavoidable.

Recalls and compliance failures carry multimillion-pound costs

A single escaped error can erase margins, disrupt supply chains, and weaken retailer relationships.

Retailers now expect automated, provable compliance

Manufacturers without real-time, tech-enabled controls face increasing pressure, including delisting and lost contracts.

How Agentic Manufacturing Operations Work

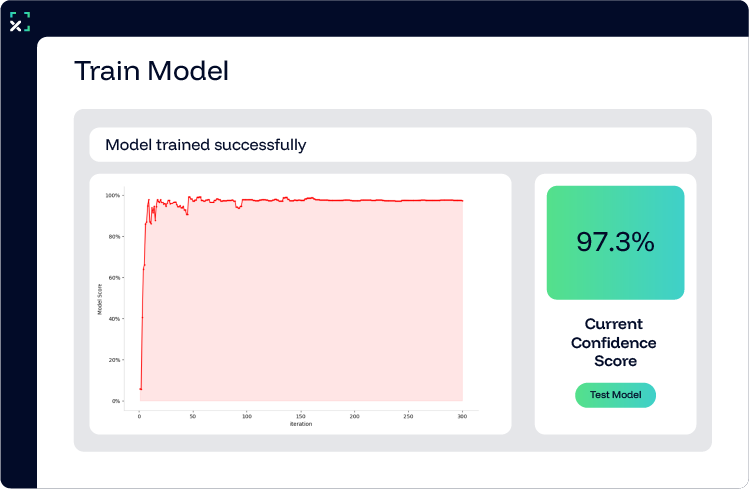

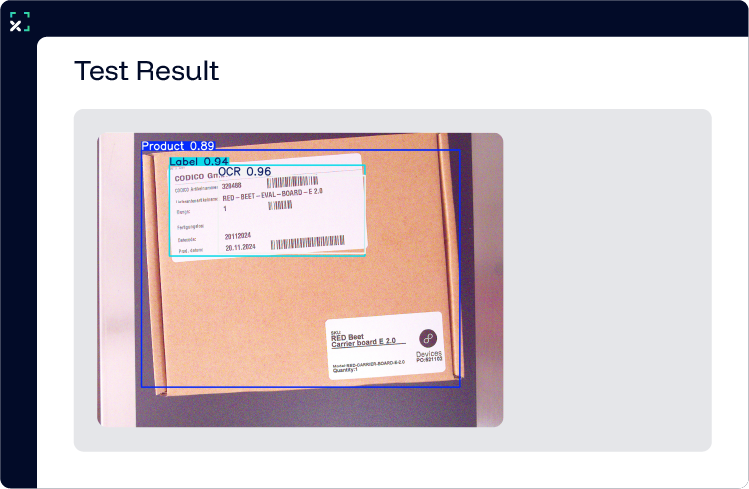

Thingtrax AI agents actively observe production, reason over live conditions, and autonomously intervene effectively preventing errors, enforcing standards, and optimising line performance as events unfold.

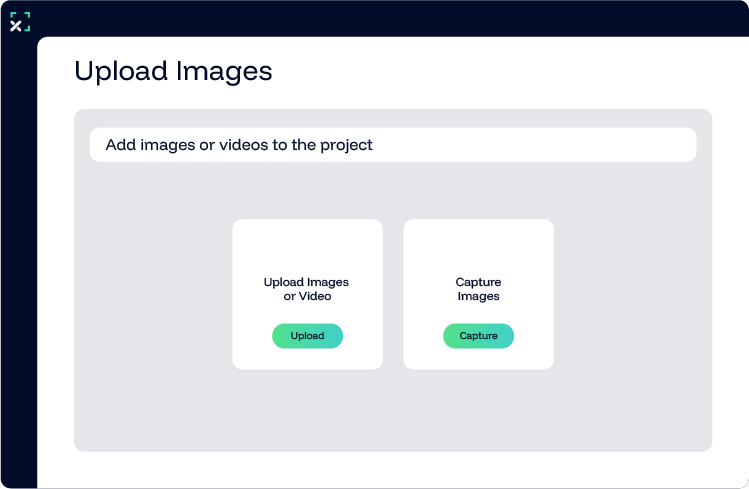

Capture

Cameras capture real-time video

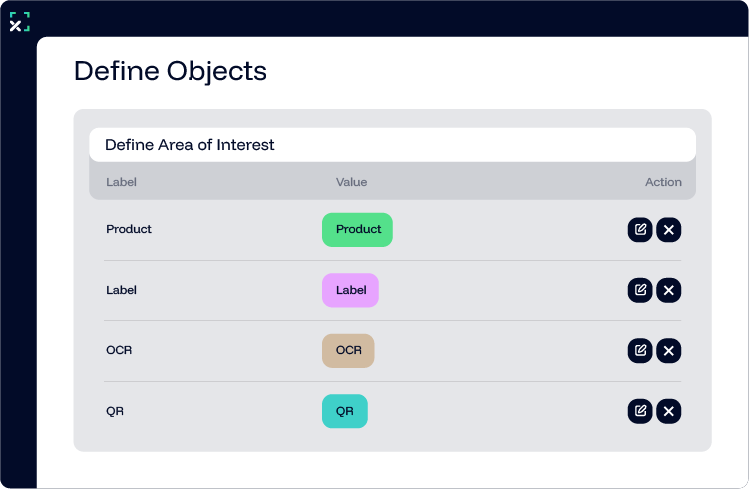

Analyse

Physical AI agents interpret the video

Act

AI agents trigger actions

A Composable Agentic Operations Platform

Thingtrax is a composable platform of AI agents deployed directly on the production line. Manufacturers can start with the agents they need today and expand across the line over time — all coordinated through a shared orchestration layer that preserves end-to-end optimisation.

No changes to your existing line. No loss of control. No fragmentation

Meet the Out-of-the-Box AI Agents

Each AI agent operates independently at the line while contributing to a shared orchestration layer — enabling coordinated, line-level optimisation

Orchestrating AI Agents Across the Entire Line

Thingtrax’s orchestration layer is what transforms individual AI agents into a true Agentic Manufacturing Operations platform.

Multiple agents work together across the line — sharing context, coordinating decisions, and triggering actions in real time.

Line efficiency is the outcome of orchestration, not dashboards, reports, or disconnected tools.

Use Thingtrax’s built-in line efficiency platform or integrate with existing enterprise systems to support continuous improvement at scale.

Build & Extend with Custom AI Agents (Coming Soon)

The Thingtrax Agentic Manufacturing Operations Platform is designed to support the creation of custom AI agents tailored to unique operational requirements — all governed by the same orchestration and intelligence layer. This future capability enables manufacturers to extend agentic operations beyond today’s use cases while maintaining consistency, control, and coordinated decision-making.

Why Manufacturers Choose Thingtrax

AI agents detect and remove faults instantly, without slowing the line.

Issues are resolved the moment they occur, not after reports are reviewed.

Multiple agents working together deliver sustained efficiency gains.

Start with one agent, expand across lines and sites seamlessly.

Reduced waste, rework, and recall risk within weeks.

From product to pallet, Thingtrax ensures every item is accounted for, every specification is enforced, and every line operates at peak efficiency.

Trusted by Leading Food and Beverage Brands

Fast to Install – Built to Deliver

Modular AI agents deploy independently – minimising disruption while accelerating impact.

Flexible Pricing That Scales With You

Pay for the AI agents you deploy today – and scale incrementally as your operational needs evolve.

Ready to See Thingtrax in Action?

See how agentic manufacturing operations deliver immediate, measurable impact on food and beverage production lines.